|

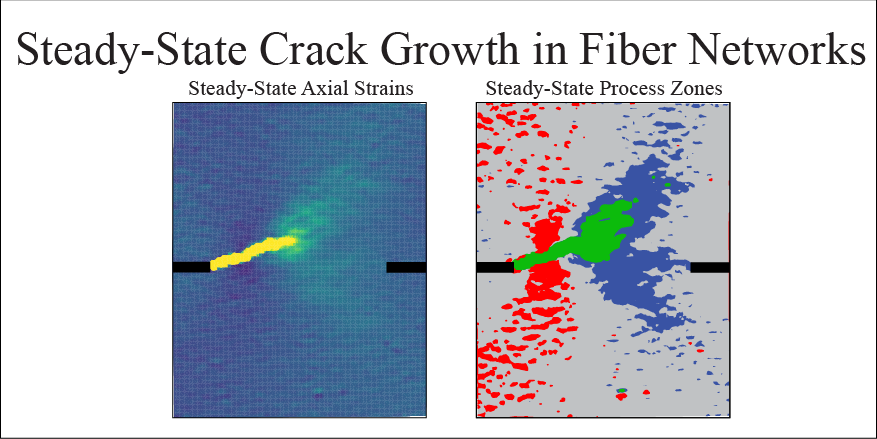

What do aluminum foil and sheets of paper have in common? Steady-state crack growth! Cracks in Al foils and sheets of paper grow under fully-plastic conditions, even though the deformation and failure mechanisms are very different. Metallic materials at room temperature deform via dislocation motion, which is an isochoric process. Fracture of aluminum foils is peculiar- a transverse necking mechanism creates a void-free fracture surface that has almost 100% reduction in area. In contrast, paper is a porous, network-structured material where reconfiguration and deformation of the wood fibers lead to plastic strains. Fracture in paper is mostly due to interfiber bond failures (and some fiber fracture), and the fracture surface is “hairy” because the fibers pull away from each other. Below (left) is an image of an axial strain field for a crack in paper growing at steady-state. Our latest manuscript, “Mode I crack growth in paper exhibits three stages of strain evolution in reaching steady-state,” has been published in Theoretical and Applied Fracture Mechanics (https://doi.org/10.1016/j.tafmec.2022.103279). This new work explains how growing cracks reach steady-state in a wood fiber network-structured materials- paper. We used high resolution, full-field digital image correlation (DIC) to capture and identify the process zones (image below, right). Through 4/18/22 you can access at https://authors.elsevier.com/a/1efbLcAT7Ejp5

0 Comments

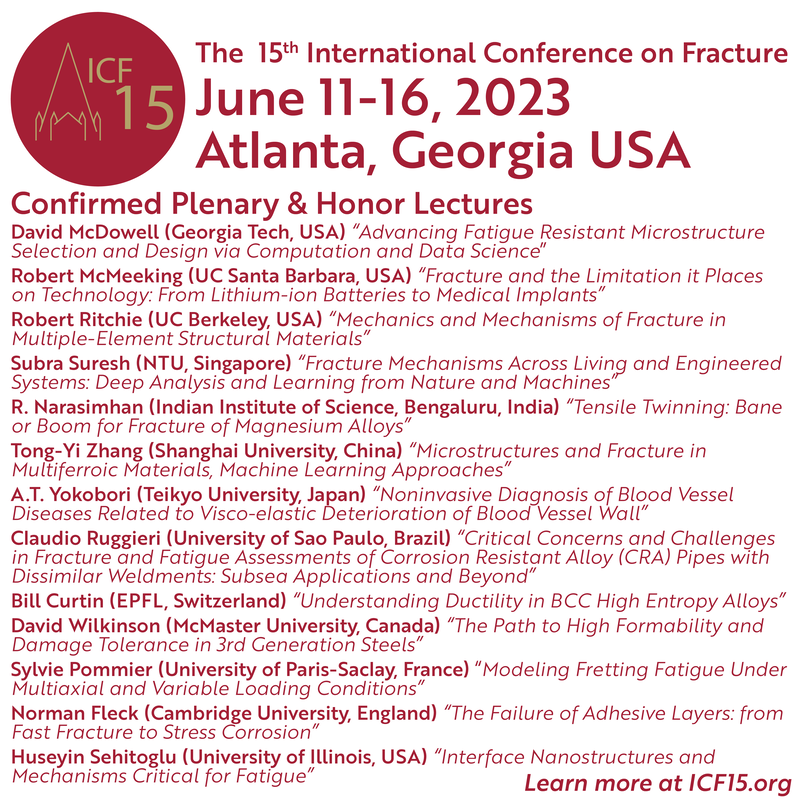

Ashok Saxena (University of Arkansas), Rick Neu (Georgia Tech), and I have been working since 2016 to bring the 15th International Conference on Fracture (ICF15) to North America. Large, in-person events like ICF15 require years of planning, even without a worldwide pandemic! Here is our amazing lineup of Plenary & Honor lectures…

|

AuthorC.L. Muhlstein ArchivesCategories |

RSS Feed

RSS Feed